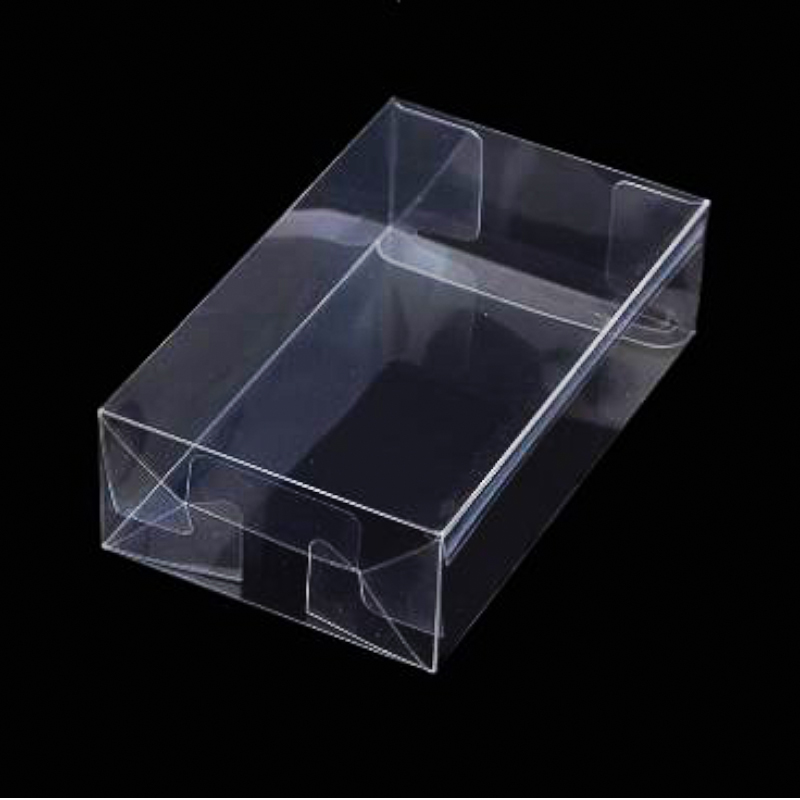

Products

PVC transparent plastic box

Five Advantages Of Products

- Good performance of raw materials, in order to obtain a better printing color effect.

- The higher the second, the better the smoothness of the box.

- For fine printing products, the finer the mesh line and the smaller the dot diameter, the more smooth the rubber box raw materials should be used for printing, so as to make the original reproduction good.

- The higher the glossiness of the plastic box, the more reflective light the surface will be like a mirror, and the more bright the appearance will be.

- The smoother the rubber box raw material, the higher the gloss, the higher the gloss of the printed product color.

Product Details

The performance of PVC, PTE and PP, the raw materials of plastic box, determines the quality of printing ink. Only the raw materials with good performance can obtain better color rendering effect. Therefore, it is of great practical significance to correctly understand the relationship between the performance of rubber box and the color of printed products, and reasonably select high-quality raw materials for printing according to the characteristics of printing products and process conditions.

1. The relationship between the smoothness of glue box and the color rendering effect

Smoothness is a technical index to evaluate the concave convex degree of the rubber box surface. It is a physical quantity indicating the smoothness, smoothness and evenness of the rubber box surface. That is, under a certain vacuum condition, the time required for a certain volume of air to flow between the rubber box test sample surface and the smooth glass surface under a certain pressure is measured, and its unit is expressed in seconds. The higher the second, the better the smoothness of the box. The smoother the rubber box is, the more uniform and complete the contact between the material surface and the plate during printing, the more sufficient the ink layer transfer on the layout (relief) or blanket, and the better the color rendering effect of the printed matter. On the contrary, poor smoothness of the rubber box raw materials, ink transfer is not uniform, not enough, and the surface of the raw materials on the amount of ink permeability is strong, the color effect is poor, often easy to make the ink color of printed matter flowery, light. Therefore, the finer the screen wire and the smaller the dot diameter, the more smooth the rubber box raw materials should be used for printing, so as to make the original reproduction good.

2. Relationship between glossiness of plastic box and color rendering effect

Glossiness refers to the specular reflection degree of the surface of the rubber box, expressed as a percentage. The higher the glossiness of the plastic box, the more reflective light the surface will be like a mirror, and the more bright the appearance will be. In fact, in addition to specular reflection, there is also diffuse reflection on the surface of the plastic box, which makes the glossiness of the box decrease. Glossiness of the plastic box raw materials, printing ink color is also more bright, ink visual effect is good. It can be said that the smoother the rubber box raw material, the higher the gloss, the higher the gloss of the printed product color. There is a close relationship between the glossiness and smoothness of the raw materials of the rubber box, but the glossiness is not smoothness. The glossy surface of the raw materials of the rubber box is not necessarily the smooth surface. From the glossiness characteristics of the raw materials of the plastic box, it is of practical significance to select the appropriate raw materials for printing according to the characteristics of the printed parts. For example, for books and periodicals with text as the main page, the paper with general glossiness should be selected to avoid reflection, so that the eyes will not be tired if they look at it for a long time. For the printing plate based layout, PVC, pet and PP materials with high gloss should be selected to make the ink color uniform, thick and bright.

Dongguan Shengyuanxin Industrial Co., Ltd.

Contact Person: Mr. Lu

Telephone: +86 13763131972

Landline: +86 0769-85267793

Company Address: No. 2, Huanhu Road, Shutian Avenue, Humen Town, Dongguan City, Guangdong, China

Website: www.syxpacking.com

Previous: Pet transparent plastic box

Next: Electronic blister box